Description

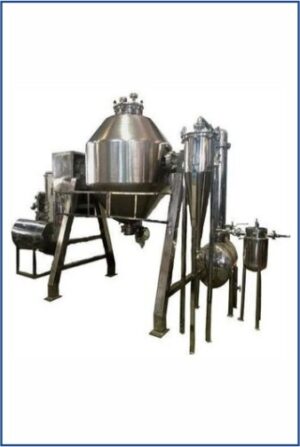

TWIN SHAFT DISPERSER:

Twin Shaft Dispersers are considered as most versatile equipment for paint production. As the name suggests, the disperser range has been specifically designed to disperse, mix and homogenize products. The process of dispersion is carried out by the centrally located shaft having Saw tooth impeller & running at high speed (~1000 rpm), and the slow speed Anchor is responsible for the mixing Action. Reckoned for trouble-free operations, the equipment made available in this range is extensively used for manufacturing plastic emulsions, solvent based Paints and Eco-friendly water based paints.

MODEL CAPACITY

Standard Machines with following working capacities are available.

Liters : 10 Ltrs to 15000 Ltrs.

M.O.C

MS, (IS 2062 Gr A/B, SA 516 Gr 60/70) SS316, SS304, SS316L, SS304L.

TSD LIMITATION:

- Dead volumes in the vessel are very high.

- Small batch size less than 75% of rated capacity cannot be effectively processed.

- Dispersion time is more.

- Only cowl disc type disperser can be provided due to inclined mounting

- The bearings need changing frequently for high speed shaft.

- Powder charging can be done only when anchor stirrer is in working condition and the dispersion is in stationery condition.

- Powder dusting on top of vessel is very high.

HIGH SPEED DISPERSER:

High Speed Disperser (Hydraulic Lifting) has dispersing and mixing function, which used for mass production; Equipment with inverter has steeples speed, can operate for a long time. It has stable running and low noise; Mixing disc is easy to be replaced, and can change different forms of dispersing discs according to production technology. Lifting structure adopts hydraulic cylinder as actuator, stable lifting, integrated hydraulic station, environmental and without leakage. It is an ideal grinding machine for materials with many varieties and many colours.

MODEL CAPACITY

Standard Machines with following working capacities are available.

Liters : 10 Ltrs to 15000 Ltrs.

M.O.C

MS, (IS 2062 Gr A/B, SA 516 Gr 60/70) SS316, SS304, SS316L, SS304L.

HIGH SPEED DISPERSER PRODUCT FEATURES:

=> Drive Head

A steel fabricated enclosure inside which is installed the drive assembly consisting of a set of balanced pulleys, V belts, electric motor and motor tensioning device. The drive head is of hinged type construction which can be opened for maintenance.

=> Main Shaft & Dispersing Disc

A SS 304 shaft duly machined and balanced is provided with a cowless disperser blade of special design for quick and efficient dispersion. The dispersers blade is made from special steel to withstand high wear and tear. The shaft is installed in a bearing housing provided with taper roller bearings. Lubrication points are provided on the housing.

=> Lifting & Lowering

The entire drive head and shaft is mounted on pneumatic lifting system which can be lifted and lowered to clear the height of the vessel.

=> Electric Motor

TEFC motor, drives a set of pulleys and V belts. The Motor is provided with a belt tensioning device. The motor details are 380 V / 50 Cycles / 3 Phase RPM 1500

=> Speed Inverter

An AC Frequency inverter installed in a panel controls the RPM of the Disperser shaft from 0-1500. The inverter is provided with settings for monitoring torque, amperage, voltage, power factor etc and is PC compatible

=> Electric Control Panel (Non-Ex proof)

A control panel is provided with the following functions. Main motors on off, ammeters, voltmeter, emergency stop, inverter trip, indicating lamps, speed control switch, RPM indicator. All internal wiring is per international codes of practice.

=> Electric Control Panel (Ex proof)

A remote control panel is provided with the following ex proof controls. Main motors on off, ammeters, voltmeter, emergency stop, inverter trip, indicating lamps, speed control switch, RPM indicator. All internal wiring is per international codes of practice. The inverter is installed in a separate panel and is to be installed in a safe Non-Ex proof zone.

=> Cover for The Tank

The cover is attached with the shafts and lifted up and down together by hydraulic system

=> Vessel Locking Device (Optional)

A vessel locking device consisting of locking arms, cantering device, and manually operated locking screw is provided.

=> Vessel (Optional)

The vessel is fabricated from SS plates and is provided with 3 nos castor wheels, SS bottom discharge ball valve and towing handles. All SS parts are duly polished inside and outside.

Reviews

There are no reviews yet.