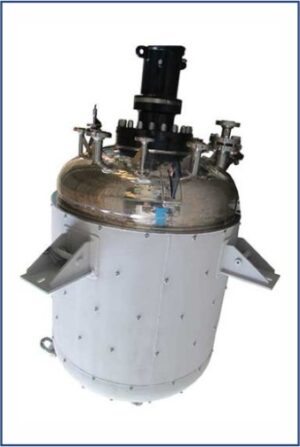

Description

Roto Cone Vacuum Dryer OR Double cone vacuum Dryer is best suited for drying materials like water/solvents from wet powder received after filtration units because these materials are not capable of resisting high temperature levels and materials that are poisonous and strong irritants. These are also useful in averting oxidized and volatile materials that require to be retrieved. The product runs on high-tech mechanism performs ideally under vacuum. In addition, it also allows for better drying process, temperature operation as well as economical process through total solvent recovery system.

Salient Features/ MOC (In GMP Model):

- Low drying temperature, fast drying.

- Uniform drying.

- Easy to clean internal surface.

- Reduces drying time

- Inner shelve Cone and contact parts in SS 316.

- Stearn /HW water Jacket in SS 304.

- Insulation with jacket in SS 304.

- Cyclone separator in SS 316.

- Condenser (shell & tube) and Receiver in SS304

- Butterfly valve (SS316) at discharge port with dummy and hand wheel.

- Stand and Structure in SS 304/MS with SS304 cladding. Drive unit enclosed with SS304 Covers.

- Dry Mechanical Seal for vacuum side.

- Dry Mechanical Seal for Waterside.

- FLP Motor & FLP Control panel enclosed in SS304 panel.

- Digital Temperature Indicators (FLP) at Hot Water inlet and outlet.

- Digital Temperature Indicator (FLP) and Dial Vacuum Gauge in vapour line.

- Digital Temperature Controller (FLP) with Pneumatic Valve at Hot water inlet.

- Provision for Nitrogen purging Vacuum release with interlocking to isolation valve.

- Temperature and Vacuum Gauges (Dial Type) on Cone.

- Safety Guard/railing telescopic type with limit switch (FLP) with interlocking.

- Drain plug and safety valve on HW/Steam Jacket.

- Pulse jet type dust filter is provided inside the cone.

- Positioning wheel /inching button for cone.

M.O.C

MS, (IS 2062 Gr A/B, SA 516 Gr 60/70) SS316, SS304, SS316L, SS304L, SS904, Hastelloy, Duplex, Inconel, Monel, PTC, Rubber Lined, FRP Lined, Halar Coated, Lead Lined.

Capacity: 500Ltrs to 15KL

TECHNICAL SPECIFICATION:

|

Capacity (Ltr.) |

Working Volume (Ltr.) |

Power (HP) |

RPM |

SPACE REQUIRED Width Depth Height |

||

|

500 |

250 |

3.0 |

6 |

2100 |

2000 |

2000 |

|

750 |

400 |

5.0 |

6 |

3000 |

2400 |

2500 |

|

1000 |

500 |

5.0 |

6 |

3500 |

3300 |

2800 |

|

1500 |

750 |

7.50 |

5 |

3500 |

3300 |

3300 |

|

2000 |

1000 |

10.00 |

5 |

3500 |

3600 |

3500 |

Reviews

There are no reviews yet.